- Insights & events

- Success stories

Success stories

Each year, 4flow works with its customers to complete numerous successful projects. Explore a selection of supply chain success stories from across various industries.

Contact us

Filter by category

- Automotive supplier (4)

- Life sciences (1)

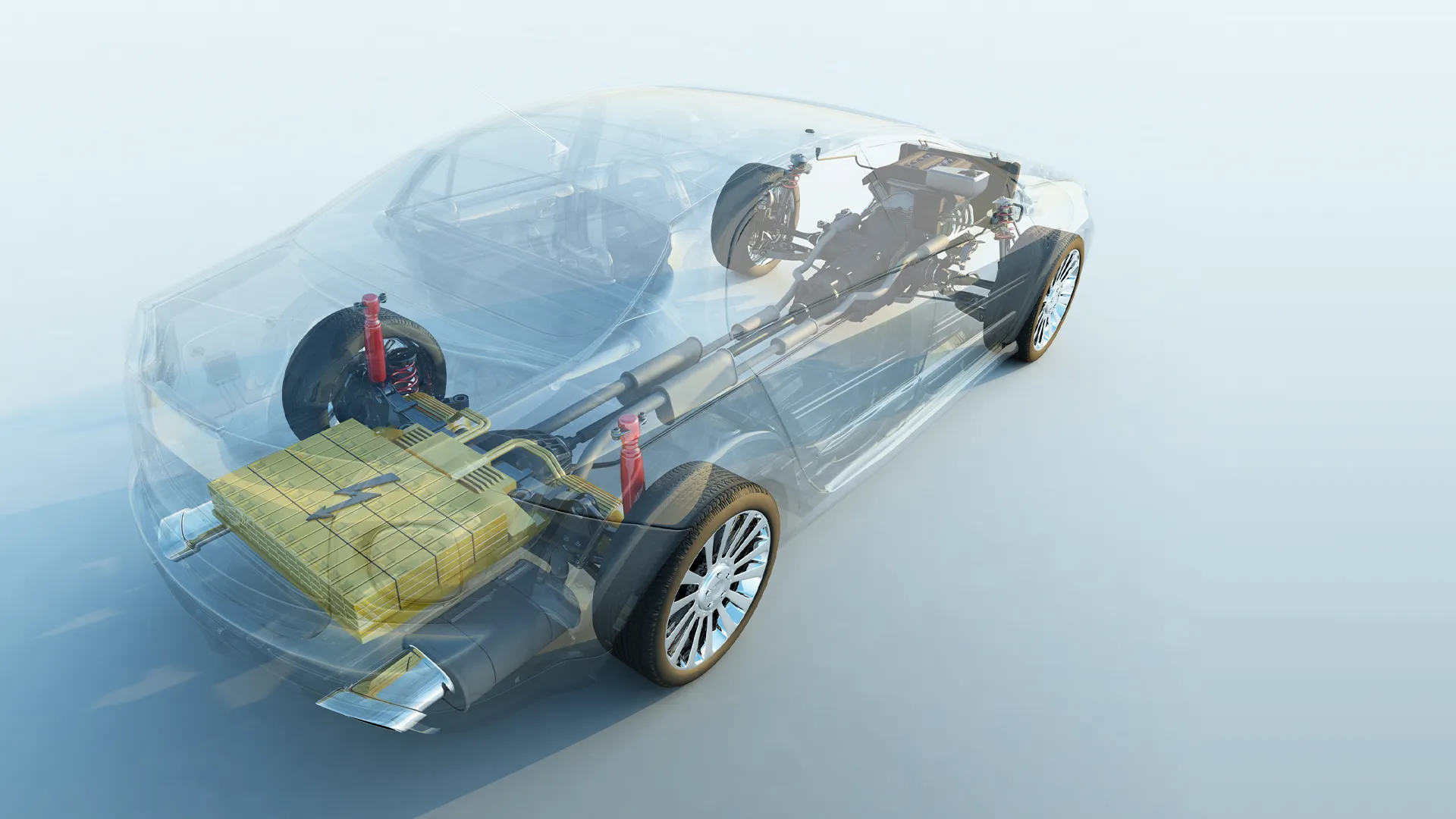

- Automotive manufacturing (6)

- Communications (1)

- Energy (1)

- Small and medium businesses (1)

- Consumer goods & retail (7)

- Machinery manufacturing (2)

- High-tech (4)