- Software

- Integrated material and transportation planning software

Seamlessly connect processes with 4flow TORO for better material and order planning results and improved transportation utilization

Break down planning silos

Cut costs by 20%

- Go live in just 2 months

-

Benefits

-

Use cases

-

Case studies

-

FAQs

-

Discover your saving potential

Is disconnected planning hurting your bottom line?

Late transport planning, organizational silos, and inefficient manual processes negatively impact material planning. 4flow offers 20+ years of integrated expertise in consulting, software, and services. Unlock measurable cost savings, improved utilization and sustainable results with a unique approach.

-

Do you frequently need to adjust plans to make them actionable for transportation?

-

Do your material and transportation planning teams work in silos, reducing overall efficiency?

-

Are manual processes limiting your truck utilization?

Optimize your supply chain by integrating material and transport planning early on

Supply chain planning

- Supply chain planning

- Transportation planning

- Material planning

Break down inefficient planning silos

Integrate material and transport planning for more efficiency and lower costs

Harmonize planning across functions

Integrate transportation constraints into material planning and eliminate inefficient replanning

Establish structured planning flows

Align teams and eliminate costly ad hoc decisions with standardized processes

Enable smooth supply chain execution

Early coordination across teams ensures reliable planning and fewer disruptions

Reduce logistics costs at scale

Save costs through early planning alignment without sacrificing service quality

Maximize truck utilization

Bundle shipments and align truckloads to reduce empty space and freight spend

Prevent costly last-minute changes

Early planning optimization reduces shipment volatility and coordination effort

Reduce costs with early planning

Factor in transport cost drivers from the start to avoid missed savings

Boost agility with smarter planning

Maintain control of your supply chain and adapt to volatility with flexible, data-driven planning

Adapt shipments without disruption

Adjust call-offs dynamically to balance transportation, inventory, and demand

Stabilize demand and planning

Proactive planning makes for stable demand and prevents the need for reactive adjustments in transportation

Increase flexibility, not spending

Align planning decisions early on and enable adaptability without cost penalties

Harmonize planning across functions

Integrate transportation constraints into material planning and eliminate inefficient replanning

Establish structured planning flows

Align teams and eliminate costly ad hoc decisions with standardized processes

Enable smooth supply chain execution

Early coordination across teams ensures reliable planning and fewer disruptions

Maximize truck utilization

Bundle shipments and align truckloads to reduce empty space and freight spend

Prevent costly last-minute changes

Early planning optimization reduces shipment volatility and coordination effort

Reduce costs with early planning

Factor in transport cost drivers from the start to avoid missed savings

Adapt shipments without disruption

Adjust call-offs dynamically to balance transportation, inventory, and demand

Stabilize demand and planning

Proactive planning makes for stable demand and prevents the need for reactive adjustments in transportation

Increase flexibility, not spending

Align planning decisions early on and enable adaptability without cost penalties

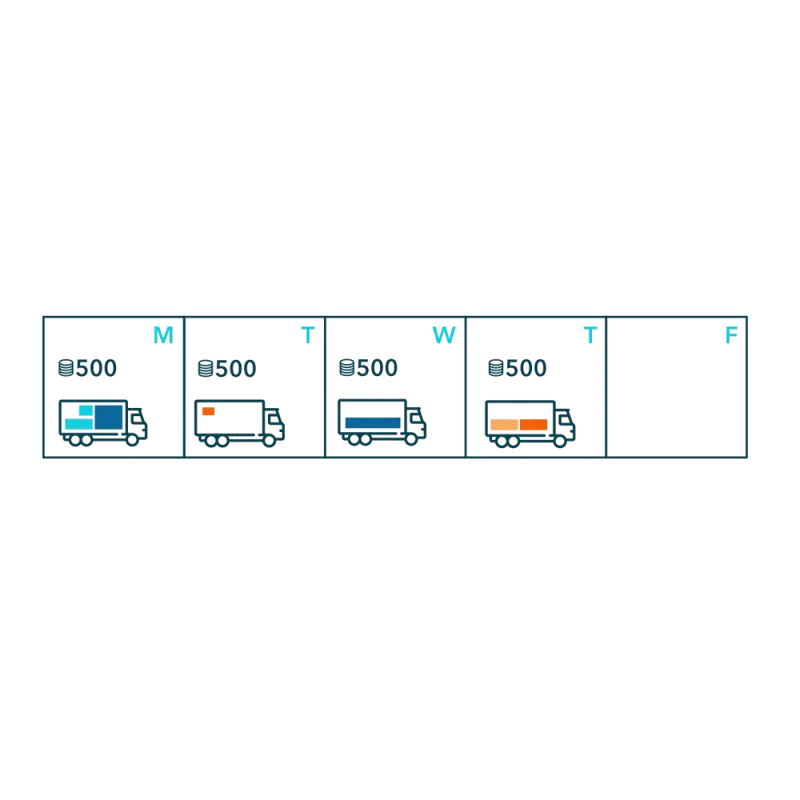

Maximize utilization, cut costs

Align call-offs and shipments early to boost truck loads and reduce freight spend

Increase truckload utilization and cut costs

Align call-offs with transport capacity to build fuller, cost-efficient loads

Increase planning stability

Account for transport needs early to streamline workflows and enable stable planning

Automate integrated planning

Use smart algorithms to arrange loads and shipments directly in material planning

Communicate better and plan ahead

Improve transport planning quality by reducing costly last-minute adjustments

Align call-offs and transportation planning

Factor in transport constraints early to prevent last-minute schedule shifts

Avoid peaks and extra shipments

Balance demand and avoid costly peaks by shifting call-offs within time windows

Create stable, executable plans

Reliable plans provide stability and enable better collaboration across teams

Automate and streamline planning

Reduce manual effort and create consistent, efficient transport planning workflows

Connect planning to your existing IT

Data-driven transportation planning with seamless ERP and TMS integration

Create consistent planning flows

Structured transport workflows replace ad hoc tasks and reduce planning complexity

Seamlessly connect planning tasks

Cross-functional planning for feasible shipment schedules and fewer team silos

Increase truckload utilization and cut costs

Align call-offs with transport capacity to build fuller, cost-efficient loads

Increase planning stability

Account for transport needs early to streamline workflows and enable stable planning

Automate integrated planning

Use smart algorithms to arrange loads and shipments directly in material planning

Align call-offs and transportation planning

Factor in transport constraints early to prevent last-minute schedule shifts

Avoid peaks and extra shipments

Balance demand and avoid costly peaks by shifting call-offs within time windows

Create stable, executable plans

Reliable plans provide stability and enable better collaboration across teams

Connect planning to your existing IT

Data-driven transportation planning with seamless ERP and TMS integration

Create consistent planning flows

Structured transport workflows replace ad hoc tasks and reduce planning complexity

Seamlessly connect planning tasks

Cross-functional planning for feasible shipment schedules and fewer team silos

Early planning for reliable supply

Fewer last-minute changes through transport-aligned material planning

Provide feasible delivery schedules

Create executable plans by aligning with real transport constraints

Avoid costly call-off adjustments

AI-driven algorithms bundle call-offs early on for stable, efficient schedules

Improve planning visibility

Leverage KPIs and dashboards to align call-offs with transport capacity

Balance inventory without extra costs

Avoid stockouts with smart planning aligned with transportation

Optimize material call-offs early

Avoid late changes and coordination effort through early constraint checks

Standardize planning adjustments

Apply smart planning rules to prepone call-offs and reduce inventory fluctuation

Reduce manual workload

Minimize manual work and last-minute changes with standardized, automated planning processes

Streamline routine planning

Handle daily call-off decisions with built-in logic – no short-term changes needed

Replace spreadsheets and workarounds

Move from manual patchwork to a connected, system-driven planning approach

Focus on proactive planning

With fewer disruptions to handle, you can spend your time improving processes and material flow

Provide feasible delivery schedules

Create executable plans by aligning with real transport constraints

Avoid costly call-off adjustments

AI-driven algorithms bundle call-offs early on for stable, efficient schedules

Improve planning visibility

Leverage KPIs and dashboards to align call-offs with transport capacity

Optimize material call-offs early

Avoid late changes and coordination effort through early constraint checks

Standardize planning adjustments

Apply smart planning rules to prepone call-offs and reduce inventory fluctuation

Streamline routine planning

Handle daily call-off decisions with built-in logic – no short-term changes needed

Replace spreadsheets and workarounds

Move from manual patchwork to a connected, system-driven planning approach

Focus on proactive planning

With fewer disruptions to handle, you can spend your time improving processes and material flow

Shift orders to facilitate consolidation and minimize costs

Many companies perform transportation optimization too late – either during execution or in tactical planning stages. At this stage, the opportunity to consolidate shipments has passed, leading to underutilized trucks and high transportation costs. Volatile demand makes effective consolidation difficult, often resulting in excessive freight spend and emissions.

4flow TORO shifts shipment planning to an earlier stage, enabling dynamic consolidation of material and sales orders. The solution bundles shipments for better truck utilization and lower costs, long before transport execution. Integrated 3D load planning reduces empty space, making your transportation more sustainable and efficient.

Key capabilities for cost reduction

-

Dynamic order preponement

Reschedules material and sales orders to bundle shipments and improve truck utilization

-

Sustainability optimization

Reduces CO₂ emissions by minimizing unnecessary shipments and increasing load efficiency

-

3D load planning

Visualizes optimal truck loading to minimize empty space and streamline shipment planning

Integrate planning across your networks

In many organizations, order and call-off planning is siloed from transportation planning, focused only on production or customer needs. This disconnect leads to underutilized shipments, last-minute changes, and high transportation costs across inbound, intercompany, and outbound flows.

4flow TORO connects material and order planning with transportation planning in one integrated system. Transportation constraints are considered early, enabling better decisions, fewer adjustments, and greater efficiency. The software automates shipment consolidation across supply chain stages and transport types – from FTL and FCL to LTL, LCL, and milk run for material and empty flows – ensuring optimal utilization and lower transportation costs at every step.

Key capabilities for end-to-end planning

-

Streamlined shipment execution

Optimizes inbound, intercompany, and outbound shipments early for lower costs and better results

-

Cross-mode load optimization

Ensures efficient container and truck usage across FTL, FCL, LTL, LCL, and milk run shipments

-

Elimination of planning silos

Aligns material, order, and transport planning to avoid conflicts and reduce late-stage changes

Automate and accelerate planning without IT complexity

Transportation and supply chain planning is still often managed manually, using spreadsheets, outdated tools, or fragmented systems. The result? Inefficiencies, significant manual work, and limited flexibility to respond to change.

4flow TORO automates transportation-relevant planning steps to significantly reduce manual workload. The system supports seamless ERP and TMS integration, or it can be deployed quickly using a CSV workflow – ideal if you’re looking for fast, low-complexity optimization. Either way, you can make a smooth shift from reactive, manual planning to automated, data-driven decision-making without the need for lengthy IT projects.

Key capabilities for automated planning

-

Automated shipment planning

Reduces planner workload by adjusting call-offs and shipments automatically

-

Flexible system integration

Integrates with ERP and TMS systems or works with CSV upload for quick deployment

-

Reduction of manual workload

Transforms reactive processes into data-driven planning with fewer errors and more efficiency

Trusted by industry leaders

Contact us

How much could you save on transportation?

Discover your savings potential in just three steps, completely obligation-free:

- Contact us to schedule a call

- Provide call-off or order data for 5-10 sample lanes

- Hear back with your savings potential within one week

Case studies: Proven results with 4flow TORO

Discover how leading companies use 4flow TORO to overcome silos, minimize supply chain costs, and improve delivery performance.

- Full truck optimization

- Partial load optimization

FAQs

Yes. 4flow TORO enables a phased rollout by starting with selected suppliers or lanes that have good data. Master data can be continuously improved and enriched during ramp-up.

4flow TORO limits inventory impact by controlling how far orders are preponed. Typically, only 10–20% of order lines need to shift to unlock savings. Users can fine-tune settings per material or lane.

Absolutely. 4flow TORO offers flexible options – from Excel-based workflows to full ERP/TMS integration. Start simple and scale integration at your own pace.

4flow TORO works with or without a TMS. It can operate as a stand-alone system or enhance existing TMS setups by pre-optimizing shipments, improving both efficiency and cost savings.

A first go-live typically takes 2–6 months, depending on your IT setup and scope. The process includes design, integration, testing, training, and go-live preparation in a structured rollout.

By consolidating or splitting call-offs, 4flow TORO improves truck and container utilization, reduces LTL shipments, and delivers up to 20% savings on transportation costs.

Yes. 4flow TORO supports road, sea, and air. It optimizes across FTL, LTL, FCL, LCL, and milk run shipments.

Most customers see ROI in 6-12 months. Key drivers: fewer shipments, better utilization, and lower costs – compared to minimal inventory impact and implementation effort.

4flow TORO dynamically adjusts call-offs within planning windows, balancing material availability and transport efficiency. This reduces disruptions and improves truck utilization.

A TMS executes transportation. 4flow TORO plans ahead – optimizing truck loads before call-offs are sent. 4flow TORO works 1-90 days in advance; a TMS manages shipments up to 48 hours in advance.

Used in combination, 4flow TORO pre-optimizes shipments, enhancing TMS performance for lower costs, higher truck utilization, and fewer disruptions.

You can quickly see your optimization potential in a few clicks with our free online calculator.

If you’d like a more detailed analysis of your cost savings potential, or an estimate tailored to your network, our 4flow experts are happy to help. We can calculate your optimization potential for you free of charge based on a sample of your call-off or order data. Contact us to get started.