- Consulting

- Supply chain planning & optimization

- Warehousing and production

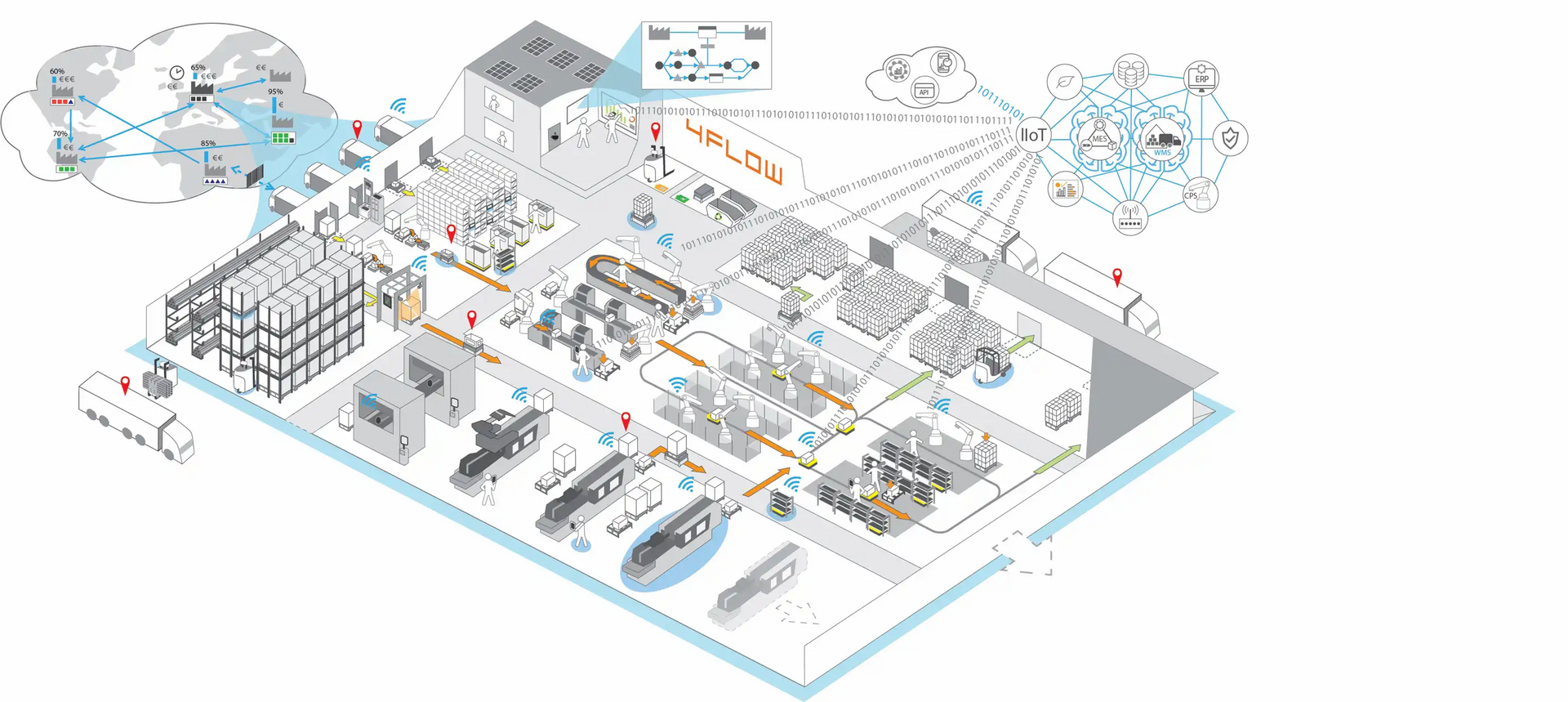

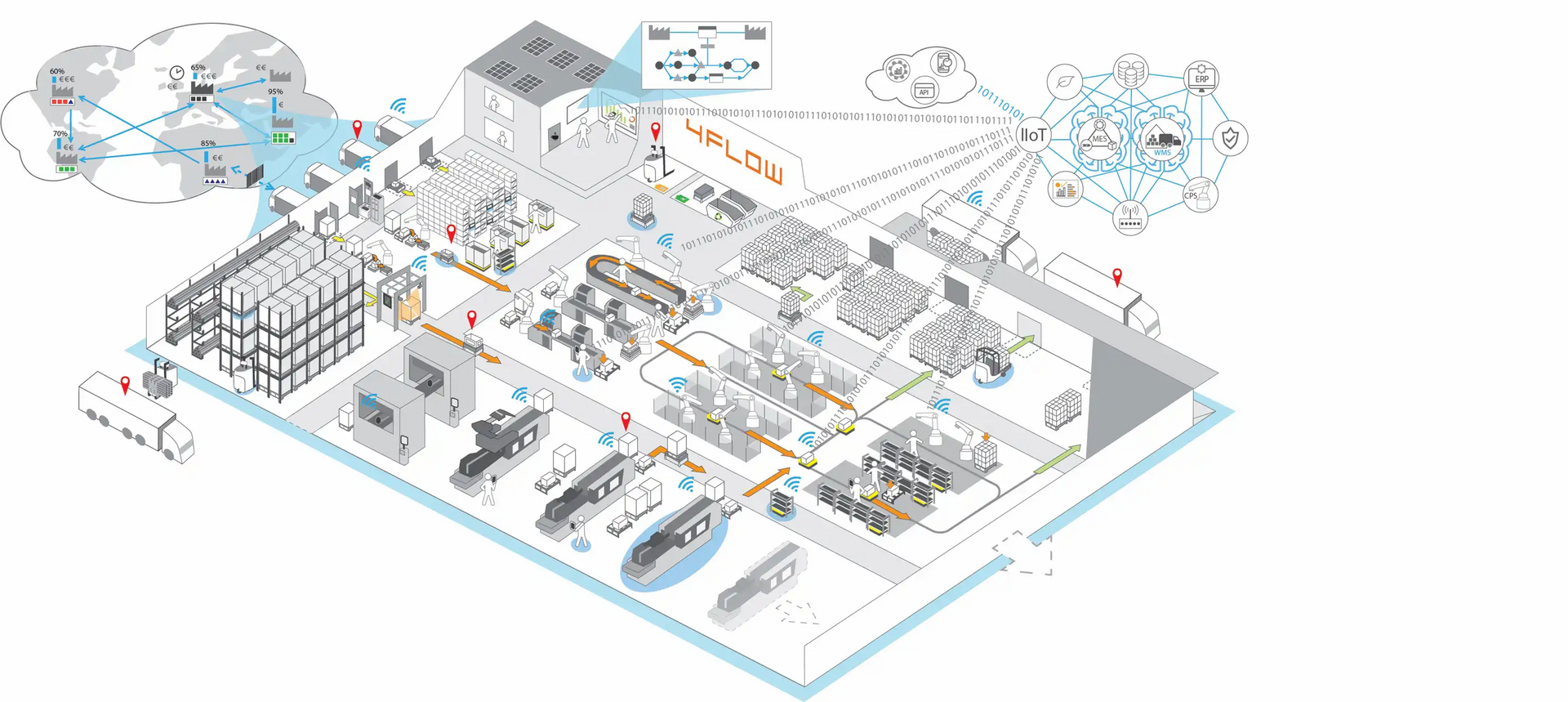

Future-proof your production and intralogistics network through strategic planning, seamless digital integration and advanced automation

Benefit from expert guidance throughout your factory journey – from initial strategic decisions to successful go-live

Increase your competitiveness with the right level of automation

- Optimize and connect your end-to-end production network

How can you ensure that your production and logistics systems remain efficient even as you face rising costs, increasing uncertainty and evolving requirements? And what steps can you take to improve resilience throughout your entire production network?

4flow helps you answer these key questions. We support you to optimally plan and implement new warehouses and factories, transform your production environment into a smart factory, boost efficiency in intralogistics and optimize your entire production network.

How we optimize your production and intralogistics networks

Factory design and implementation

Whether greenfield or brownfield, every factory planning project starts with strategic questions about your target system:

- What is your production strategy?

- Which articles or parts need to be considered?

- What degree of automation do you aim to implement?

- What does your future growth look like?

- Does your plan include multiple construction stages?

Your answers to these questions create the framework for all further planning. Our experts support you to develop and implement each part of your factory planning – including your new processes, layout, material and information flows, organizational structures and IT systems.

Smart factory

Technologies such as IoT, automation and AI are often used as stand-alone solutions in production environments. The key to unlocking their full potential is the seamless integration of processes, data streams and systems.

4flow supports you every step of the way toward your smart factory. We start with a comprehensive analysis of your starting point, and we help you develop an optimal target vision and a concrete implementation strategy. We connect physical, digital and organizational structures to create a seamless smart factory ready for agile, efficient and future-proof production.

A smart warehouse with connected processes

A smart warehouse with connected processes

Process and material flow optimization

With an integrated approach, 4flow helps you quickly and significantly improve efficiency in your intralogistics network. We provide you with transparency over process costs and the degree of your system maturity. Based on data-driven analyses and shop floor inspections, we develop concrete measures to boost efficiency, and we support you to implement them. Our goal: measurable results for your business from day one.

Production footprint optimization

Increasing protectionism, high energy costs, and limited access to rare raw materials are just some of the reasons behind recent shifts in value creation networks. The right production footprint should reflect these changes and account for future uncertainties.

4flow supports you to develop an optimized and customized production network, considering both location and network planning. Reduce your costs and increase the resilience of your network with our proven approach.

Sound interesting?

Contact usThe benefits of optimizing your production network with 4flow

-

Tailored location strategy

Future-proof your production network with a customized approach that balances cost efficiency, scalability and resilience.

-

Sustainable cost savings

Accelerate throughput times and unlock substantial cost reductions in your factories and warehouses.

-

Enhanced operational productivity

Implement targeted measures to boost productivity across your operations.

-

Smart factory transformation

Rely on expert guidance from strategy development to full-scale implementation as you transition toward a smart factory.

-

Proven warehouse best practices

Access industry-specific best practices and draw on a database of over 10,000 benchmarks to optimize your processes, organization and IT.

-

Decades of intralogistics excellence

Leverage our extensive track record in intralogistics and production to drive sustainable success for your business.

What our customers say

Proven success with top businesses

- Mars

- HelloFresh