- Consulting

- Warehouse & distribution

- Digital intralogistics

4flow consulting

Digital intralogistics

Autonomous in-house transportation systems, AI-supported dynamic demand forecasting and flexible automated warehouse systems are not just visions of the future – they are already being implemented into supply chains by digital leaders today. These innovations, however, are often utilized as unsynchronized standalone solutions. As a result, even forward-thinking businesses are far from realizing the potential that can be harnessed from the harmonized consolidation of supply chain functions in a smart factory or warehouse.

Challenges on the path to digital intralogistics

Most businesses do not have concrete plans to digitize their supply chains, and initial momentum often wanes once pilot projects are completed. And while many single automation solutions are well-known, the possibilities of integrated information processing are often less apparent. Complete transparency about current and future digital intralogistics solutions does not currently exist.

End-to-end approaches are the key to future autonomy

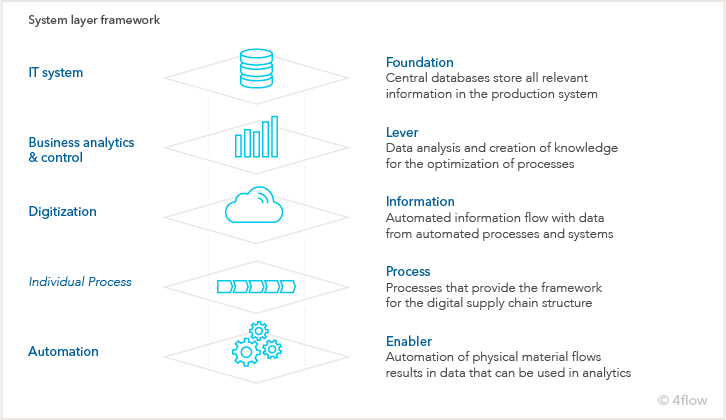

4flow works together with businesses to determine how they can adapt from their existing situations to develop a target strategy and clearly define the next steps towards a digital intralogistics. This means integrating different IT systems, automation solutions, identification technologies and digital scheduling as well as utilizing data from business analytics & control applications along the process chain. With its proven system layer model, 4flow combines these different relevant layers in a structured manner.

4flow system layer framework

4flow system layer framework

Using sprints to quickly reach a technological target strategy

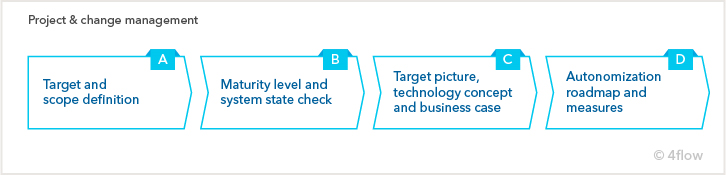

With its proven project approach, 4flow works together with customers to quickly develop a customized roadmap and a technological target strategy to enable the continuous and structured development of the supply chain. The project approach is divided into four consecutive sprints.

4flow’s project approach for developing an autonomization roadmap

4flow’s project approach for developing an autonomization roadmap

- Sprint A: In the first sprint, organizational goals, system specifics and logistics principles are compared and weighed against one another. The requirements determined during this process define the possible set of solutions.

- Sprint B: The current state of the supply chain system is then analyzed and evaluated using the 4flow maturity level model.

- Sprint C: Next, a comprehensive digital intralogistics target strategy is developed and established using suitable technological solutions.

- Sprint D: Finally, a target strategy with concrete measures is developed and chronologically structured in a roadmap.

The consistent autonomization of supply chain functions holds enormous cost and efficiency potential in terms of space, inventory, handling and transportation. 4flow enables businesses to reach this potential with its many years of experience in developing individual and goal-oriented implementation strategies.

What 4flow offers:

- Complete transparency about current material and information flow technologies

- A roadmap for intralogistics autonomization based on individual needs

- Many years of experience in developing and implementing digitization initiatives for in-house supply chains

- Close and independent collaboration with innovative intralogistics technology providers as well as 4flow research